Types of Flow Meters | Flowmeter | Flow Measurement

What is a Flow Meter? Types of Flow Meters

Flow meters play a crucial role in managing and controlling production processes effectively in industrial facilities. They precisely measure the flow rate of liquids or gases passing through, thereby enhancing production efficiency, enabling energy savings, and improving product quality. In this article, we will delve into the importance and varieties of flow meters in industrial processes.

The Importance and Varieties of Flow Meters in Industrial Processes

Industrial facilities rely on accurate flow measurement for efficient management and control of production processes. Flow meters, therefore, play a vital role in this context. By precisely measuring the quantity of liquid or gas passing through, flow meters enhance production efficiency, facilitate energy conservation, and contribute to product quality improvement. In this article, we will explore in detail the significance of flow meters and their various types in industrial processes.

Types and Functions of Flow Meters

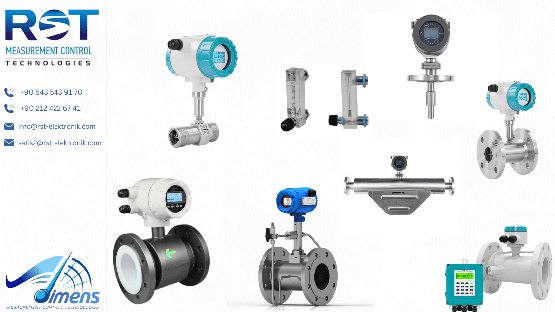

Flow meters come in various types tailored to different applications and requirements. Each type of flow meter is designed to meet specific industrial needs. The most common types of flow meters include:

- Multivariable Flow Meters: Used to measure the flow of multiple fluids or components simultaneously. They are particularly useful for measuring the flow of multiple gases or liquids in a pipeline.

- Differential Pressure Flow Meters: Determine the flow rate by measuring the pressure difference created within a pipeline. These meters operate based on the principle of differential pressure measurement.

- Volumetric Flow Meters: Measure the flow rate using a turbine or other mechanical elements. They are often preferred for high flow rates.

- Turbine Flow Meters: Measure the flow rate by relating it to the rotational speed of turbines. Due to their high accuracy and rapid response times, they are widely used in many industrial applications.

- Helical Flow Meters: Measure the flow rate using a helical structure. These meters provide high accuracy even at low flow rates.

- Mass Flow Meters: Directly measure the mass flow of fluid. They ensure precise measurement of liquid and gas flows on a mass basis.

- Rotameters: Measure flow rate using a visual indicator. They display the fluid level within a tube on a gauge, providing information about flow rate.

- Annubar Flow Meters: Measure flow rate using a type of sensor. By determining the velocity and pressure of the fluid inside the pipe, they calculate the flow rate.

Flow Meter Selection and Factors

Choosing the right flow meter requires considering several factors. These include the physical properties of the fluid, flow conditions and range, process temperature and pressure, material selection, pipe size, and accuracy requirements. Correct flow meter selection is crucial for ensuring reliable and accurate flow measurement, vital for the efficiency and product quality of facilities.

Flow Meter Technology and Developments

Flow meter technology is continuously evolving. Advanced flow meter types, such as electromagnetic flow meters, ultrasonic flow meters, vortex flow meters, and Coriolis flow meters, offer high precision and reliability, catering to a wide range of industrial applications. These advancements enable more precise and reliable measurements in industrial processes, enhancing efficiency and reducing costs.

Conclusion

Flow meters play a critical role in effectively managing industrial processes. Proper flow meter selection enhances efficiency, reduces costs, and improves product quality in facilities. Additionally, the functionality and variety of flow meters are crucial for the success of industrial facilities. Therefore, the correct selection and use of flow meters are essential for the efficient management and optimization of industrial processes.