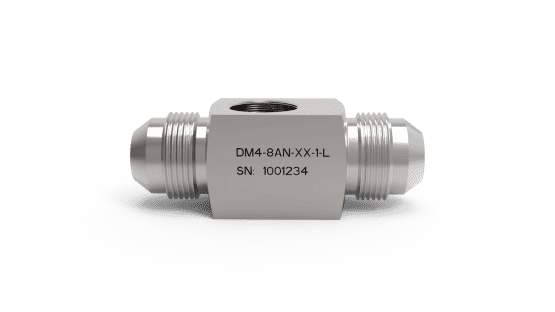

Trigas Turbine Flowmeter DM4-8 | 0,1 l/min to 13 l/min

Demanding measurements are best handled by turbine flow meters. Turbine flowmeters from TrigasDM are created specifically for these types of solutions if you require features like the ones listed below:

- High precision

- Quick response times

- Compact style

- Superior dependability during continuous operation

- Variable flow changes

- Varying viscosity and operation temperatures

These types flowmeters can be used for a wide range of applications for professional works like:

- monitoring the flow rates of fuels coolants or lubricants used in engine and engine construction

- dosages in the food and beverage industry

- pharmaceutical industry

- monitoring and measuring ultrapure water during research.

Technical Properties

- Flow Range: 0,95 l/min to 12 l/min (0.25 GPM to 3.2 GPM)

- Extended Flow Range: 0,1 l/min to 13 l/min (0.03 GPM to 3.4 GPM)

- Operating Pressure: up to 540 bar

- Pressure Loss (at 70% linear flow): 0,19 bar

- Temperature Range: -270°C to 400°C (-454°F to 752°F)

- Response Time: <3 ms

- Calibration Accuracy: ≤±0,03% of measurement

- Repeatability: ≤±0,05% of measurement

- Linearity in Linear Flow Range: ≤±0,5% of measurement

- Linearity with Linearizer: ≤±0,1% of measurement

- K-Factor: 8700 Impulse/l

- Max. Frequency: 1950 Hz

- Housing and Turbine Material: Stainless Steel

- Ball Bearing Material: Ceramic bearings, Steel cage

- Weight: 161 g

- Inner Diameter: 7,6 mm

- Length: 62,2 mm

- Connection: AN threaded connection

- Connection Size: ½“

- Connection Thread: ¾“ -16UNJF-3A

- Prefiltration: 10µ (Recommended)

- Inlet: 76 mm (Recommended)

- Outlet: 38 mm (Recommended)

- Standard viscosity: 1,3 mm²/s

-

PRODUCT REQUEST FORM