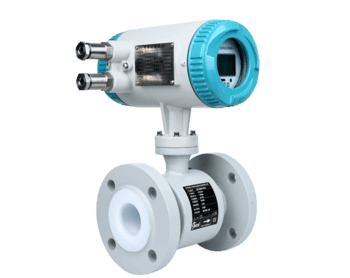

Electromagnetic Flowmeters

Electromagnetic flowmeters are a common type of flowmeter used to measure the flow rate of a fluid, usually a liquid. These flowmeters work by utilizing the conductivity of the fluid and are named after the principles of electricity and magnetism.

How Do They Work? Electromagnetic flowmeters contain a sensor mounted in a pipeline. As the fluid passes through the pipe, the magnetic field inside the sensor measures the conductivity of the fluid, which depends on the amount of ions or cations present in the fluid.

A magnetic field is created and passed through the fluid. Ions or cations in the fluid generate an electric current as they move within this magnetic field. This electric current is proportional to the flow rate and is measured by the sensor to determine the flow rate of the fluid.

Advantages and Areas of Use Some advantages of electromagnetic flowmeters are:

High Precision: They can make precise measurements and generally operate with high accuracy. Reliability: They provide reliable results with their durable structure and accurate measurements. Low Maintenance: They are generally low maintenance and long-lasting. Wide Flow Range: They can operate at different flow rates and provide accurate results over a wide flow range. These flowmeters are widely used in many industrial applications such as water and wastewater treatment plants, chemical processes, petrochemical industry, and the food and beverage industry.

Electromagnetic flowmeters are a widely used technology for accurately and reliably measuring the flow rate of fluids. With their high precision, reliability, and wide range of uses, they are important tools for many industrial processes.

-

PRODUCT REQUEST FORM